Low MOQ for Iron-Base Amorphous Alloy Ribbon - Nanocrystalline Cores for Current Transformer (LLE-CT) – LLE

Low MOQ for Iron-Base Amorphous Alloy Ribbon - Nanocrystalline Cores for Current Transformer (LLE-CT) – LLE Detail:

Nanocrystalline Cores for Current Transformer(LLE-CT)

Normal standard core dimensions:

|

No. |

Bare core dimensions(mm) |

Finished core dimensions (mm) |

No. |

Bare core dimensions (mm) |

Finished core dimensions (mm) |

||||||||

|

ID |

OD |

Ht |

ID |

OD |

Ht |

ID |

OD |

Ht |

ID |

OD |

Ht |

||

|

1 |

4.3 |

7.3 |

2.8 |

3.7 |

7.8 |

3.3 |

41 |

19.0 |

27.0 |

8.0 |

16.5 |

29.2 |

9.8 |

|

2 |

6.5 |

9.8 |

4.5 |

5.1 |

11.2 |

5.7 |

42 |

20.0 |

25.0 |

6.5 |

18.2 |

27.4 |

9.4 |

|

3 |

8.0 |

12.0 |

4.5 |

6.3 |

13.8 |

6.5 |

43 |

20.0 |

26.0 |

10.0 |

17.9 |

27.7 |

12.7 |

|

4 |

8.5 |

15.3 |

5.0 |

7.4 |

16.8 |

6.3 |

44 |

20.0 |

30.0 |

10.0 |

17.8 |

32.2 |

12.5 |

|

5 |

9.5 |

15.5 |

20.0 |

7.7 |

17.3 |

22.5 |

45 |

20.0 |

32.0 |

10.0 |

17.8 |

34.0 |

12.5 |

|

6 |

9.6 |

13.2 |

10.0 |

8.5 |

15.0 |

12.0 |

46 |

20.0 |

30.0 |

15.0 |

17.8 |

33.1 |

17.5 |

|

7 |

10.0 |

14.0 |

5.0 |

8.5 |

15.0 |

12.0 |

47 |

23.0 |

33.0 |

25.0 |

22.0 |

36.7 |

29.8 |

|

8 |

10.0 |

16.0 |

5.0 |

8.5 |

17.8 |

6.8 |

48 |

25.0 |

32.0 |

8.0 |

22.0 |

35.1 |

11.1 |

|

9 |

10.0 |

16.0 |

8.0 |

8.3 |

18.2 |

10.3 |

49 |

25.0 |

32.0 |

6.5 |

22.0 |

35.1 |

8.7 |

|

10 |

10.0 |

18.5 |

5.0 |

8.0 |

20.8 |

6.6 |

50 |

25.0 |

32.0 |

10.0 |

22.0 |

35.1 |

12.4 |

|

11 |

10.0 |

22.0 |

10.0 |

8.1 |

24.3 |

12.8 |

51 |

25.0 |

40.0 |

10.0 |

21.8 |

43.0 |

13.5 |

|

12 |

11.0 |

18.0 |

8.0 |

9.1 |

20.0 |

10.2 |

52 |

25.0 |

40.0 |

12.5 |

22.5 |

42.2 |

16.0 |

|

13 |

11.0 |

18.0 |

10.0 |

9.1 |

20.0 |

12.2 |

53 |

25.0 |

40.0 |

15.0 |

21.7 |

43.0 |

18.8 |

|

14 |

11.0 |

23.0 |

20.0 |

9.8 |

26.4 |

23.2 |

54 |

25.0 |

40.0 |

20.0 |

21.3 |

44.0 |

24.6 |

|

15 |

12.0 |

20.0 |

5.0 |

10.0 |

21.7 |

7.1 |

55 |

28.0 |

34.0 |

8.0 |

25.6 |

36.8 |

10.5 |

|

16 |

12.0 |

20.0 |

8.0 |

10.6 |

21.2 |

10.2 |

56 |

30.0 |

40.0 |

10.0 |

27.6 |

43.0 |

13.7 |

|

17 |

12.0 |

20.0 |

10.0 |

10.6 |

21.8 |

12.0 |

57 |

30.0 |

41.0 |

15.0 |

27.6 |

44.2 |

18.5 |

|

18 |

13.2 |

21.5 |

10.0 |

11.5 |

24.0 |

12.9 |

58 |

32.0 |

38.0 |

6.5 |

29.6 |

40.5 |

9.3 |

|

19 |

14.0 |

19.0 |

6.5 |

11.8 |

22.1 |

9.0 |

59 |

32.0 |

44.0 |

6.5 |

29.6 |

46.8 |

9.3 |

|

20 |

14.0 |

19.0 |

8.0 |

12.1 |

22.5 |

10.2 |

60 |

32.0 |

50.0 |

15.0 |

29.6 |

53.0 |

18.2 |

|

21 |

14.0 |

20.0 |

10.0 |

12.1 |

22.5 |

12.2 |

61 |

32.0 |

50.0 |

20.0 |

18.0 |

53.0 |

23.8 |

|

22 |

14.0 |

20.0 |

12.0 |

12.1 |

22.5 |

14.2 |

62 |

40 |

50 |

10 |

37 |

54 |

14.6 |

|

23 |

15.0 |

21.0 |

10.0 |

12.8 |

23.5 |

12.8 |

63 |

40 |

60 |

20 |

37 |

63 |

24 |

|

24 |

15.0 |

23.0 |

8.0 |

12.9 |

25.8 |

10.7 |

64 |

40 |

64 |

15 |

37 |

68 |

20 |

|

25 |

15.0 |

24.0 |

6.5 |

13.0 |

26.5 |

9.0 |

65 |

40 |

64 |

20 |

37 |

68 |

23.2 |

|

26 |

15.0 |

24.0 |

10.0 |

13.0 |

26.5 |

12.5 |

66 |

40 |

70 |

20 |

37 |

73 |

24 |

|

27 |

15.0 |

24.0 |

15.0 |

13.0 |

26.5 |

17.5 |

67 |

50 |

60 |

10 |

47 |

65 |

15 |

|

28 |

16.0 |

21.0 |

10.0 |

14.0 |

24.7 |

12.5 |

68 |

50 |

80 |

20 |

47 |

83 |

25 |

|

29 |

16.0 |

23.0 |

4.0 |

14.0 |

25.0 |

6.0 |

69 |

50 |

80 |

25 |

47 |

84 |

29 |

|

30 |

16.0 |

23.0 |

8.0 |

14.0 |

25.0 |

10.5 |

70 |

50 |

90 |

30 |

46 |

94 |

34 |

|

31 |

16.0 |

23.0 |

10.0 |

14.0 |

25.0 |

13.0 |

71 |

55 |

65 |

10 |

52 |

68 |

14 |

|

32 |

16.0 |

25.0 |

8.0 |

14.0 |

27.2 |

10.8 |

72 |

61 |

70 |

10 |

58 |

73 |

14 |

|

33 |

16.0 |

26.0 |

10.0 |

14.0 |

28.5 |

12.8 |

73 |

70 |

120 |

30 |

65 |

125 |

35 |

|

34 |

17.0 |

22.0 |

10.0 |

15.4 |

24.3 |

12.3 |

74 |

77 |

86 |

10 |

74 |

90 |

15 |

|

35 |

17.0 |

23.0 |

15.0 |

14.9 |

25.4 |

17.9 |

75 |

80 |

120 |

25 |

75 |

125 |

30 |

|

36 |

18.0 |

23.0 |

10.0 |

15.8 |

25.2 |

12.7 |

76 |

90 |

125 |

25 |

85 |

130 |

30 |

|

37 |

18.0 |

24.0 |

10.0 |

15.8 |

26.6 |

12.7 |

77 |

90 |

130 |

30 |

85 |

135 |

35 |

|

38 |

18.0 |

28.0 |

15.0 |

16.0 |

30.2 |

17.6 |

78 |

100 |

120 |

25 |

94 |

126 |

31 |

|

39 |

19.0 |

22.0 |

10.0 |

17.5 |

23.5 |

12.9 |

79 |

100 |

140 |

25 |

94 |

146 |

31 |

|

40 |

19.0 |

26.0 |

10.0 |

17.0 |

28.2 |

12.8 |

80 |

120 |

170 |

25 |

114 |

176 |

31 |

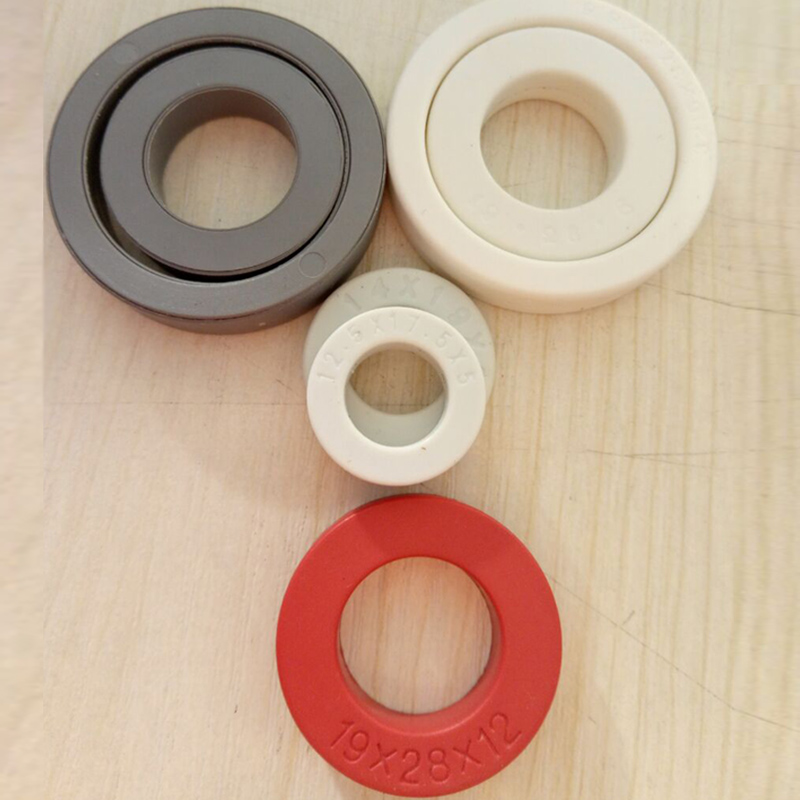

Plastic case box material:

- Polycarbonate;

- PA66,additions of 50%glass fibre;

- PBT,additions of 30% glass fibre;

- Flame resisitant ABS.

1.Features:

- High Saturate magnetic induction BS

- High initial permeability,High linearity,High Accuracy,Low phase and amplitude error for CT

- Good temperature stability(-55℃~130℃)

- Applying for transformer class grade: 0.5-0.05 Class

2.Applications:

- High precision current and voltage transformer

- Current leakage circuit breakers

- Electronic Watt hour meter

- Precision power meter

- Current control in automation industry

3.Specification:

3-1 Basic parameter

| Basic magnetic parameter | Nan-crystalline | Permalloy(Ni80Fe) |

| Saturate magnetic induction BS (T) | 1.20 | 0.70 |

| Initial permeability(GS/Oe) | 50000~100000 | 50000~100000 |

| Maximum permeability(GS/Oe) | >300000 | >200000 |

| Coercivity(A/m) | <1.6 | <0.8 |

| Density(g/cm3) | 7.2 | 8.8 |

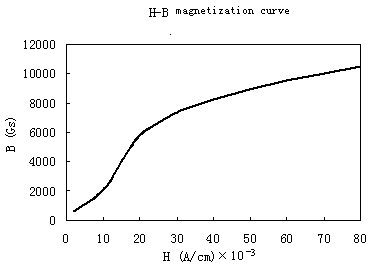

3-2 Typical magnetization curve

4.Specification and electric parameter

|

Part No. |

Core dimensions(mm) |

Finished dimensions(mm) |

Cross section |

Mean path length |

Output Voltage (mV) |

|

|

|

|

|

||

|

1 |

9.6×13.2×10 | 8.5×15.0×12.0 |

0.14 |

3.58 |

≥0.30 |

|

2 |

13.2×21.5×10 | 11.5×24.0×12.9 |

0.32 |

5.45 |

≥0.40 |

|

3 |

14×19×6.5 | 12.0×22.1×9.0 |

0.12 |

5.2 |

≥0.12 |

|

4 |

14×19×8 | 12.1×22.5×10.1 |

0.15 |

5.2 |

≥0.18 |

|

5 |

14×20×10 | 12.1×22.5×12.2 |

0.23 |

5.3 |

≥0.25 |

|

6 |

15×21×10 | 12.9×23.5×12.8 |

0.23 |

5.7 |

≥0.28 |

|

7 |

16×21×10 | 14.0×24.5×12.5 |

0.19 |

5.8 |

≥0.25 |

|

8 |

16×23×8 | 14.0×24.9×10.9 |

0.21 |

6.1 |

≥0.20 |

|

9 |

16×26×10 | 14.0×28.1×13.0 |

0.38 |

6.6 |

≥0.30 |

|

10 |

20×25×6.5 | 18.2×27.4×9.4 |

0.12 |

7.1 |

≥0.07 |

|

11 |

18×28×15 | 16.2×29.5×17.0 |

0.57 |

7.2 |

|

|

12 |

20×30×15 | 17.8×33.1×17.5 |

0.57 |

7.9 |

|

|

13 |

20×32×10 | 18.0×34.2×13.1 |

0.46 |

8.2 |

|

|

14 |

25×40×10 | 22.5×42.5×13.0 |

0.57 |

10.2 |

|

|

15 |

25×40×15 | 21.9×43.2×18.9 |

0.86 |

10.2 |

|

|

16 |

32×50×15 | 29.0×53.2×18.2 |

1.03 |

12.9 |

|

|

17 |

32×50×20 | 28.5×53.2×23.5 |

1.37 |

12.9 |

|

|

18 |

40×60×20 | 37×63×24 |

1.52 |

15.7 |

|

|

19 |

40×64×20 | 37×67×24 |

1.82 |

16.3 |

|

|

20 |

40×70×20 | 37×73×24 |

2.28 |

17.3 |

|

|

21 |

50×80×20 | 47×84×25 |

2.28 |

20.4 |

|

|

22 |

50×80×25 | 47×84×29 |

2.85 |

20.4 |

|

|

23 |

50×90×30 | 46×94×34 |

4.56 |

22.0 |

|

|

24 |

50×100×25 | 46×104×29 |

4.75 |

23.6 |

|

|

25 |

70×120×30 | 65×125×35 |

5.7 |

29.8 |

|

|

26 |

80×120×25 | 75×125×30 |

3.80 |

31.4 |

|

- Notice: Testing condition: input 10mA

- To the specification in the form, cores can be made for meeting user’s need.

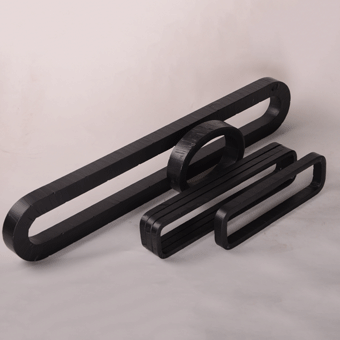

Product detail pictures:

Related Product Guide:

Large spin Hall magnetoresistance and its correlation to the spin-orbit torque in W/CoFeB/MgO structures | Amorphous Ribbon For Transformer Core

North America Dry Type Transformer Market to hit $1.5 billion by 2025: Global Market Insights, Inc. | Current Transformer Core

No matter new customer or old customer, We believe in long term and trusted relationship for Low MOQ for Iron-Base Amorphous Alloy Ribbon - Nanocrystalline Cores for Current Transformer (LLE-CT) – LLE, The product will supply to all over the world, such as: Netherlands, Italy, Armenia, Most problems between suppliers and clients are due to poor communication. Culturally, suppliers can be reluctant to question items they do not understand. We break down people barriers to ensure you get what you want to the level you expect, when you want it. Faster delivery time and the product you want is our Criterion .

The factory workers have a good team spirit, so we received high quality products fast, in addition, the price is also appropriate, this is a very good and reliable Chinese manufacturers.